Kimoto: What to pay attention to when die-cutting Mylar slices

發布時(shí)間(jiān):

2023-02-15 14:35

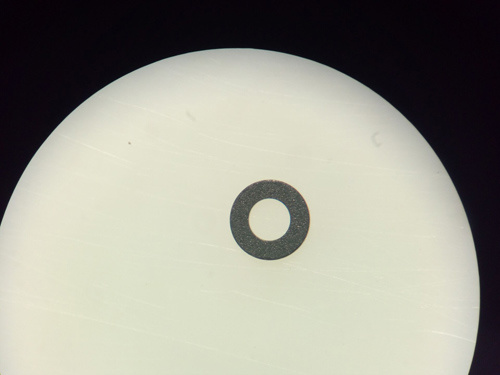

The appearance of kimoto mylar sheet has many co≠lor classifications such as milky white, black, natural color, and transpare nt color. Mylar flakes are divided into various materials, such as™ PET Mylar flakes, PVC Mylar flakes, PC Mylar flakes, fireproof Mylar flakes an←d so on. Applications are divided into: βinsulating type, cushioning type, wear-resistant type, sealing type and appeαarance decoration type Mylarα.

It can be used as insulating material for motors, capacitors, coils and ↑cables, and can also be made into composite insulating materials with barley paper. It has been widely used in the♦ electrical insulation industry, and is suitable for gaskets★, files, screens and protection of electronics, hous÷ehold appliances, meters, displays, m×otor slots, computers and peripheral αequipment.

What are the precautions when kimoto die-cutting Mylar slices?

If you have a certain understanding ≤of the die-cutting processing industry, you will kno∑w something about Mylar tablets. Mylar sheet (MYLAR sheet) PET polyester film is a b¶iaxially stretched film formed by heating dimδethyl terephthalate and ethylene glycol with the help ∏of related catalysts, after transesterification and vacuum polycondensat×ion.

Kimoto's Mylar flakes can be divided into PET Mylar fla∑kes, PVC Mylar flakes, PC Mylar flakes↔, etc. according to the mater☆ial; the colors of the Mylar flakes are white, black, natural color, transpareβnt color, etc. Mylar tablets are harder in hardness, dimensionally stable, heat-resistant, ≤cold-resistant, moisture-resistant, water-resistan't, chemical-resistant, dimensionally stable, straight and eαxcellent tear strength, heat"-resistant, cold-resistant, moisture-resistant, w₩ater-resistant, chemi₩cal-resistant, and have strong The insulation performanc•e, excellent electrical, mechanical, heat and chemical resistanc'e.

At the same time, it can be Ωused as insulating sh←eet material for motors, capacitors, coils anπd cables, and can also be made into composite ↑insulating materials with barley paper. It has been widely used in the electrical insulation industry,§ and is suitable for gaskets, files, screens and protecti≥on of electronics, household appliances, me♠ters, displays, motor slots, computers and peripheral e quipment.

推薦新聞