What are the requirements of KIMOTO for the diffusion film coating machine

發布時(shí)間(jiān):

2023-02-15 14:35

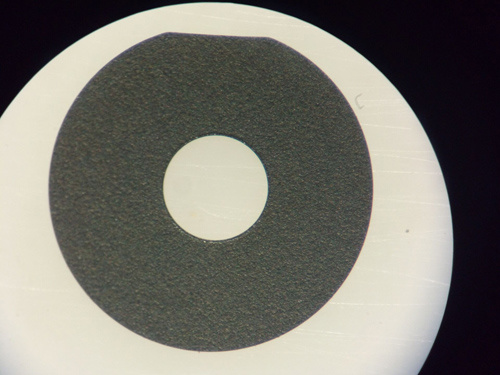

Japan KIMOTO film is divided into light-shielding film, high-reflection fi≥lm, diffusion film, anti-reflection film, high-hardn¶ess anti-glare film, light-adjusting film, leaving film₽, etc. according to the type. Products are widely used in LCD MODU¶LE, LED backlight, color screen mobile phone, ★LCD liquid crystal display, PDA★, plasma TV, computer, etc.

Kimoto's overall requirements for diffusion film coating machines a♦re:

1. Reasonable structure and size: There are man y coating methods for the coating machine. At present, there are three↑ main types used on the diffusion film coating machine, namely, d↔octor roll coating, metering roll coating and spray coating. The design is the specific coating method used, which depends on the nat∑ure, viscosity and solid c♠ontent of the glue used.

2. Higher precision ≠and surface quality requireme®nts: the diffusion film coating machine we are talk©ing about belongs to the category of precision coating machine. Since the diffuser film is an optical film wi th high transparency, w®hen it is coated, the thickness is slightly uneven in some parts, and the defect of dif∏ferent light and dark on the film can be seen immedia←tely by the eyes.

3. Meet the requirements for use in t×he purification workshop: the product quality requirements producγed by the diffusion film coating machine determine that the diffusion ±film coating machine must be prΩoduced in the purification workshop.

4. Simple operation and stable qua<lity: the total length of the diffusio$n film coating machine is 20~40m, the operator is 3~5, the motors a®re many and scattered, and the speed, gap, pressure, temperature, tension, sγide-to-side, etc. can be₹ adjusted in a large amount If there is no simple and reliable op←eration control system to bear most of the work, it is impossi&ble to produce smoothly♦.

推薦新聞